Inventory management gets a reboot in the age of lean manufacturing

Inventory management, a critical driver of enterprise supply chains, is getting an upgrade for the smart factory. Here's how.

Get the latest insights from Samsung delivered right to your inbox.

Follow Us

Get the latest insights from Samsung delivered right to your inbox.

Inventory management, a critical driver of enterprise supply chains, is getting an upgrade for the smart factory. Here's how.

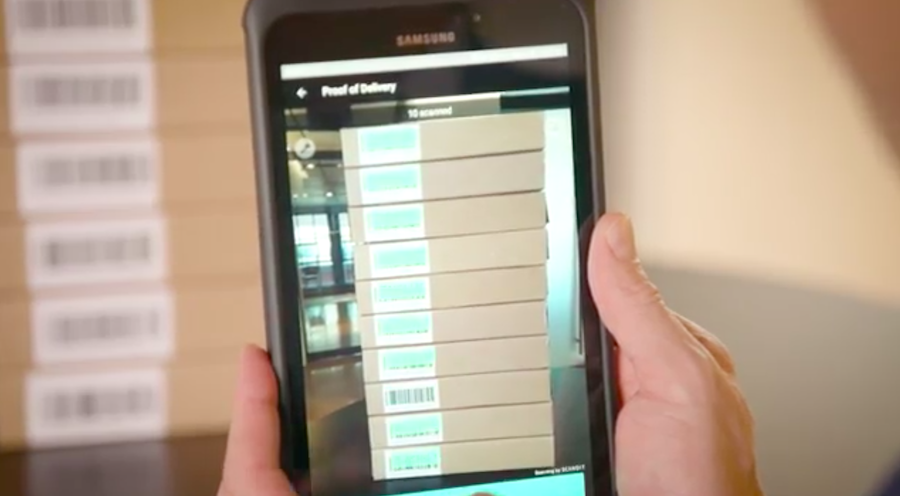

Barcode-scanning mobile devices are an efficient, cost-effective application, but harsh manufacturing environments require a ruggedized solution.

Rugged mobile scanning devices like the Tab Active2 make it a breeze to scan multiple barcodes in seconds.

Galaxy XCover6 Pro supports lean manufacturing initiatives by providing peace of mind against drops, bumps and other hazards.

Rugged mobile devices deliver connectivity to field service workers, increasing productivity wherever the job takes them.

Rugged mobile devices are allowing workers to stay safe and connected while boosting efficiencies in the oil and gas industry.

Register for an August 24 IndustryWeek webinar where Samsung and two partners discuss the benefits of transforming frontline work with mobile technology.

The Galaxy XCover Pro survived 22 grueling tests to prove it's always ready to perform, even in the toughest work conditions.

Partnering with Samsung, Pepperl+Fuchs has developed rugged devices for frontline teams in hazardous Division 2 environments.

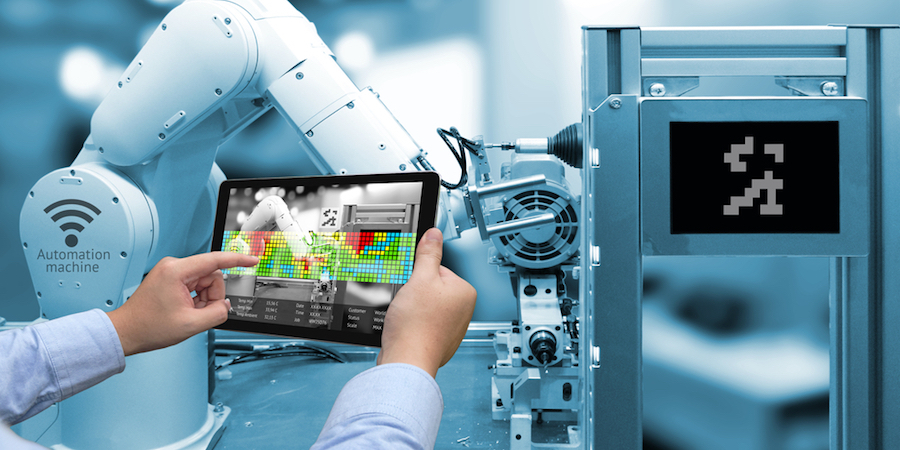

A smart factory is a data-driven enterprise. Learn how mobile devices are bringing remote robotics management to fruition.

The smart factory of the future will be driven by data. Reduce costs and drive lean manufacturing using mobile devices.

Mobility is the most efficient way to boost employee productivity in lean manufacturing and will drive tomorrow's smart factories.

Mobile devices can accelerate adoption of lean manufacturing. Here are six areas where mobility is increasing efficiency.

Tomorrow's smart factory will need to increase its manufacturing uptime. EAM software and mobile devices get the job done.

The advent of new technologies is dramatically changing how factories and manufacturing processes function.

Manufacturing companies can develop a customer-centric approach by incorporating digital smart factory principles into operations.

A confluence of technology trends such as IIoT and powerful mobile computing devices is rebooting predictive maintenance.

Companies considering a smart factory upgrade leveraging lean manufacturing techniques should keep a few guidelines in place.

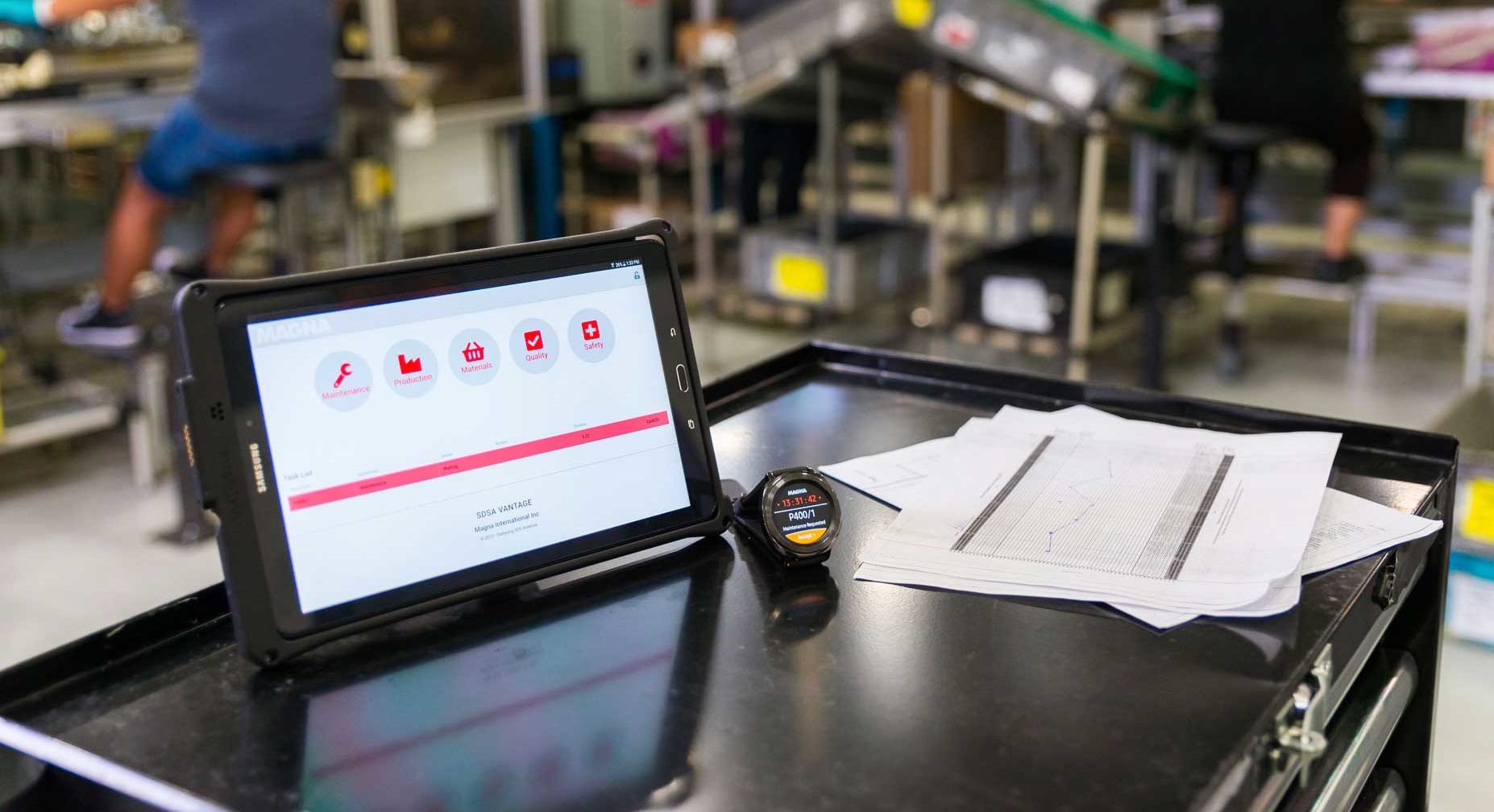

Auto parts manufacturer Magna uses wearables and tablets to improve employee communication and to help create a smart factory environment.