The Challenge

Auto Meter’s proprietary load-based testing protocol accurately analyzes a vehicle battery’s state of health, and tests the entire electrical system including the starter, alternator, cables and electrical connections. While the Auto Meter testers have worked well for many years, helping a large variety of customers reduce their warranty expense and sell more batteries, Auto Meter recognized the need to further optimize the user interface and connectivity to their cloud based data management system, AMPNET. With wireless connectivity to AMPNET, many paper-based customer processes could be fully digitized, improving data accuracy while further streamlining the test process.

The Solution

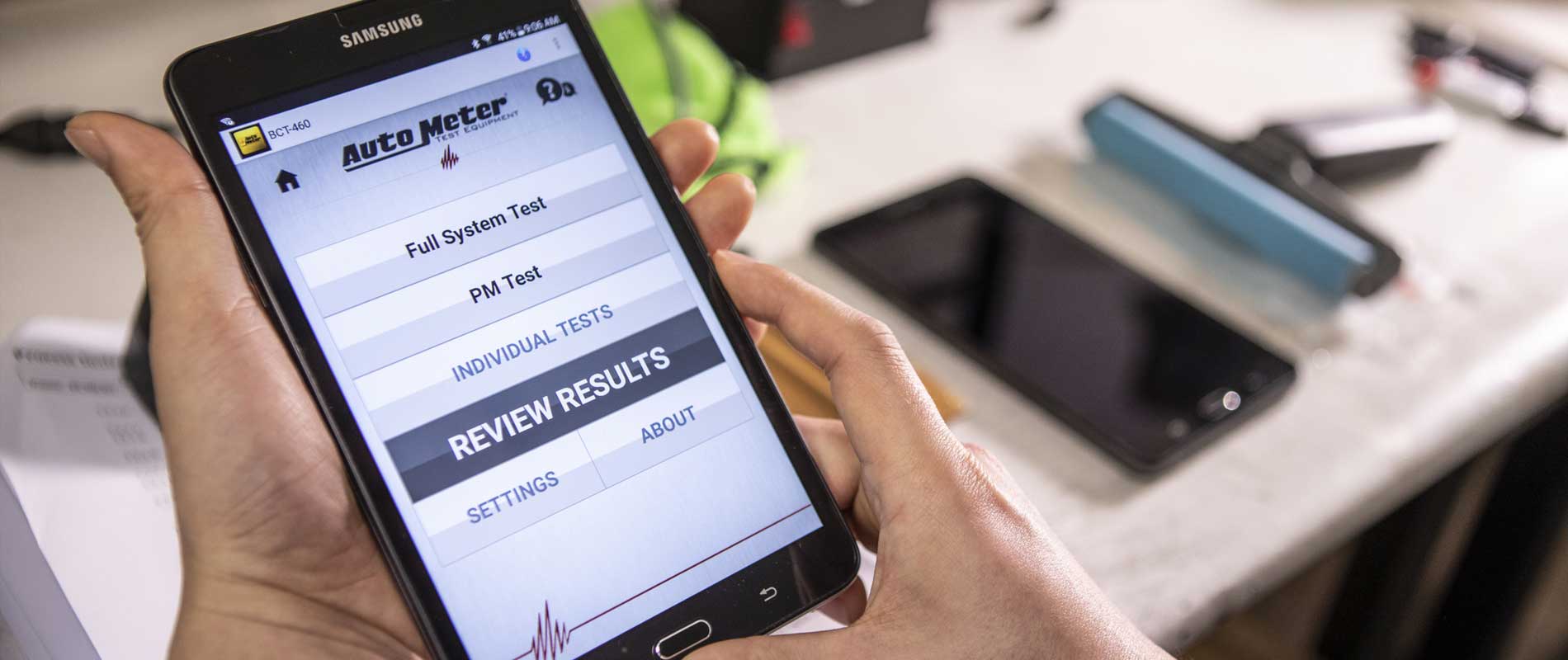

Auto Meter decided that switching to a mobile tablet for the user interface would provide an even more compelling reason for customers to buy Auto Meter testers. The company opted to build its solution on the Samsung Galaxy Tab A, which provides long battery life and the ability to read under a variety of lighting conditions, something that was an issue with the LCD screen of their previous model. Moreover, Auto Meter could now leverage Wi-Fi for data transfer and Bluetooth for wirelessly connecting the load-testing unit to the controls and readout. “The Samsung sales and technical support team was very helpful in integrating their device with our battery testing solution,” said President and COO Dean Panettieri.

Now test results automatically populate relevant forms, which completely eliminates manual entry.

The Results

Auto Meter has future-proofed its electrical testing solution by bringing it into the mobile age with the use of tablets, creating a lean solution it is proud to sell to its vehicle OEM, automotive repair and retail customers.

Use of the Samsung device has untethered technicians who can carry the device to the equipment that needs testing. This means just one technician can do the job as opposed to the two that were required earlier. The tablet has also automated much of the results delivery and handling process, fully leveraging Auto Meter’s proprietary AMPNET data management system. Now test results automatically populate relevant forms, which completely eliminates manual entry and thereby decreases chances of transcription errors. The forms are also all electronic and integrated into the data management system, allowing for a paper-free environment. Auto Meter has enabled OEMs and service shops to improve failure prediction for electrical components. Its test equipment uploads results to a cloud-based portal to create a pool of historical data that is analyzed by machine learning algorithms to detect patterns that correlate with equipment failure.

About Auto Meter

Auto Meter, headquartered in Sycamore, Illinois, and founded in 1957, focuses on instrumentation for the automotive aftermarket, with products that are widely used by performance enthusiasts and racers. The company also serves automotive OEMs, retail outlets and repair shops with a line of test equipment for vehicle electrical systems. Auto Meter’s load-based testers apply a true load to the battery, starter, alternator and cables and measures performance as a way of gauging the equipment’s health.

The Challenge

Optimize the Auto Meter Battery Testing Solution

Among other things, Auto Meter develops a line of electrical test equipment that allows technicians to accurately predict the useful life of batteries, alternators and starters. The proprietary test, compliant with the industry standard, RP-129B, accurately simulates a true electrical load on the equipment. This accuracy is invaluable to automotive repair and vehicle OEMs — it prevents them from having to replace batteries prematurely or issue warranty claims based on faulty test results.

Auto Meter has been selling their load-based testing solutions for many years, but in 2016, it decided it was time for an upgrade. Utilizing the Bluetooth-enabled Android tablet allowed Auto Meter to design a user interface that detaches from the load module that is connected to the electrical components on the engine. This allows the technician to bring the user interface behind the steering wheel of the vehicle, and perform vehicle testing wirelessly following the step-by-step testing instructions on the screen. Auto Meter’s previous heavy duty testing solution required two technicians to perform some of the testing steps: one to read testing steps from the tester that was connected to the engine electrical components, and the other to increase the engine speed at the proper time to conduct the alternator output test. Auto Meter was looking for a solution that would remove the need for a second technician, as the testing steps could be read and performed remotely using one technician due to the Bluetooth connection to the load module.

One of Auto Meter’s OEM customers previously used an electrical system testing process that required the technician to use multiple pieces of equipment, then manually record measurements and perform manual calculations to determine if there was an electrical issue with the vehicle. “This manual testing process was time consuming and prone to measurement and calculation errors,” said Dean Panettieri, COO and president of Auto Meter.

The company had also designed an in-house cloud-based data management system called AMPNET, and was looking for a solution that could automatically upload the vehicle test results and then pass that information on to OEM customers. Auto Meter’s former testing solution was quite robust, but did not have a wireless connection to the AMPNET software or the range of display graphics to pictorially show the technician where to make the tester connections to the vehicle.

The Solution

Future-Proofing Battery Testing With a Samsung Managed Mobility Solution

In 2016, Auto Meter decided to evaluate Android tablet solutions for one that could modernize and mobilize their electrical testing solution. This tablet-based tester would have all of the unique features of Auto Meter load-based testing while also providing a state-of-the-art user interface with technology-forward connectivity.

The Samsung Galaxy Tab A delivers on that promise on a number of fronts, and Auto Meter now hosts the solution on the mobile tablet.

The company also developed a ruggedized enclosure for the Samsung tablet that would allow operation under a wide variety of environmental conditions. To ensure that the industrial product is used only for the purpose for which it was created, Auto Meter relies on Knox Mobile Enrollment to deploy the tablets it sells.

With the Galaxy Tab A, a technician can perform the vehicle testing remotely from inside the vehicle’s passenger compartment following step-by-step instructional diagrams on the large display area of the tablet screen. The device’s autofocus camera is an integral part of the testing sequence, since it scans barcodes located on the vehicle (such as the VIN number) and eliminates manual input. After conducting the test, the tester automatically uploads the results to Auto Meter’s cloud-based data management system, AMPNET, using the Wi-Fi-enabled tablet. All claim and warranty forms get filled out automatically. OEMs access comprehensive test data from AMPNET and run their own predictive maintenance algorithms to determine when to proactively replace batteries, starters and alternators for fleets before they fail and cause a no-start situation.

“Long-term sustainability was one of the key things going forward, so one of the reasons we selected the Samsung Galaxy Tab A was the commitment from Samsung that the tablet would be available to us for an extended period of time. We didn’t want to have to go through a redesign process every time a model changed,” Panettieri said.

The Technology

Samsung Galaxy Tab A

Wi-Fi business tablet with long-lasting battery and thin lightweight design. Samsung Knox defense-grade security protects corporate data, and enables a comprehensive suite of mobility management solutions.

Galaxy Tab Active 2

The Galaxy Tab Active2 is a rugged tablet designed to withstand harsh conditions and equipped with the latest digital workflow tools to maximize operational efficiency.

The Results

More Efficient Testing and Recording, and Actionable Results

Panettieri reported three prime areas in which Samsung has vitally boosted product performance. First, it supported converting a testing solution that required two technicians into a testing solution that a single technician can easily perform, enhancing the marketability of the solution. “The tablet enables the load module to stay connected to the vehicle’s electrical system while the technician can be in the passenger compartment of the vehicle and control the test remotely via a Bluetooth connection, which has been a huge plus,” he said.

Second, built-in barcode scanning in the Samsung tablet has helped customers consolidate devices while providing an accurate way to capture vehicle and component data, which also makes the product more user-friendly. The autofocus camera on the Tab A reads barcodes electronically, so there’s no need for technicians to manually type them in. The new Samsung solution also automatically uploads all test results via Wi-Fi to Auto Meter’s AMPNET data management system. Forms that technicians used to have to fill out by hand for warranty claims now get populated automatically, as they too are integrated in the cloud-based system. These paperless solutions deliver greater accuracy and save time.

Finally, Auto Meter customers can now access data remotely from AMPNET and use it to garner actionable insights. “Rather than test data that is sometimes difficult to read when captured on handwritten paper forms, you can now look at trends and provide predictive analysis of when certain components are likely to fail in the near future,” Panettieri said. These capabilities allow Auto Meter to further differentiate itself from its competitors.

The Galaxy Tab A’s long battery life means technicians don’t have to worry about interruptions, and the easy-to-read screen enables use of the test equipment in a variety of lighting conditions. Finally, Auto Meter has been able to lock the devices for only their specific industrial solution, using Samsung Knox Manage.

Automation is a key component of today’s technology landscape, and Auto Meter has kept pace in a competitive industry thanks to Samsung’s mobile devices.

“The Auto Meter BCT-460 load-based tester, with an integrated Samsung tablet, accurately identifies the root cause of a vehicle’s electrical system issue the first time, whether it is the battery, starter, alternator, cables or just a poor electrical connection” said Panettieri. “This results in significantly lower warranty expense and virtually eliminates ‘no defect found’ on replaced items.” The Samsung tablet is an integral part of the value proposition to the customer with the Auto Meter BCT-460 in terms of ease of use, reduced testing labor and overall improved customer satisfaction.

“Samsung has been a fantastic business partner for Auto Meter,” he added. “Their commitment to the stability of the product enables us to provide an industrial application that is at the leading edge of technology to our customers.”