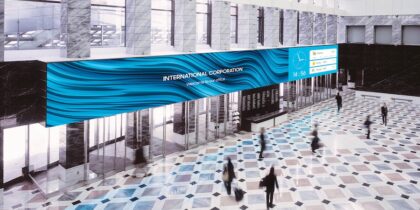

Drive 15 miles south of the Mexican border along busy expressways dotted with palm trees and rugged hills, and you’ll soon arrive at the El Florida industrial park in Tijuana, Baja California Sur. The park is huge; 45 companies, including Coca-Cola, Hyundai and Samsung, run operations and manufacturing facilities on site. With such a short drive to the border, it’s the ideal distribution center for Mexico, U.S. markets and beyond.

Starting this year, the park will serve another purpose: Prismview’s strategy for keeping project costs low and dependable.

A pivotal trade decision is made — with Prismview in the line of fire

Let’s back up. By March 2018, trade with China had become a hot-button issue for the Trump Administration, and the White House was preparing to make an announcement that would send ripples through the global economy. The President argued that China’s trade practices led to stolen U.S. technology and intellectual property — and he was ready to take action.

On March 22, 2018, the administration made their stance on trade clear. Citing USTR Section 301 violations, the President would impose tariffs of up to 25 percent on Chinese imports containing advanced technologies. The move was a show of strength — but one that had the potential to hurt US businesses as well — including Prismview.

Threatening American companies

Prismview is, and always has been, an American company. At its Logan, UT headquarters, over 350 workers hold high-paying, skilled positions in manufacturing, engineering, design, sales and operations. Prismview’s complex LED displays are made with plastic and metal components made locally, and the LED wafers are sourced from Cree, Inc., a manufacturer based in North Carolina.

But here’s the thing: LED modules, those two-sided circuit boards that Prismview workers engineer into one-of-a-kind displays, aren’t available from a US producer, nor are the module’s diodes. Prismview imports the boards from China — and with the new tariffs, the costs of those boards would increase by 25 percent.

Searching for a solution that will keep costs low

For Prismview executives, it became crucial to find a solution — and remain competitively priced. So they set to work.

Prismview’s executive team began actively lobbying Congress for an exemption from the tariffs, arguing that imported LED modules don’t pose a threat. “Assembly of LED modules in China, a relatively low-tech operation, does not place Prismview intellectual property or technology at risk,” wrote Don Szczepaniak, president and CEO of Prismview, in a submission to the U.S. Trade Representative.

While Prismview endorses the administration’s efforts to address unlawful trade practices head-on, a tariff on LED modules would not effectively change China’s behavior. In fact, it would benefit Chinese manufacturers, which already pose a sizable threat to U.S. companies. “A 25 percent tariff on our inputs will upend our supply chain, undermine our U.S. manufacturing operations and will make us uncompetitive against foreign LED manufacturers both domestically and abroad,” said Szczepaniak in his testimony to Congress. “Our Chinese competitors’ imports will not be subject to these new tariffs — putting us at a significant competitive disadvantage; particularly for the 40% of our business that comes from exports.”

Digital Signage 101

Get your complete guide to planning, budgeting and executing a successful digital signage project. Download Now

Government moves slowly, though — and Prismview needed to act quickly if they wanted to keep costs low. With help from parent company Samsung, a search began to find a plant closer to home. Quickly, all signs pointed to Mexico as the ideal location. Samsung’s manufacturing plant in Tijuana, SAMEX, is large enough to accommodate the production of electrical components for North America, Latin American and Mexico markets. With a little work and reorganization, the plant would be large enough to house parts of Prismview’s manufacturing, as well.

It’s official: Prismview’s LED modules are now manufactured in Mexico

Starting the first of this year, Prismview officially moved its LED module production operations from China to Mexico. “Prismview took immediate action,” says Candice Draper, Prismview’s Director of Production and Supply Chain. “It should have taken a year to build, train, and transfer production from China to Mexico, but it only took three months. This truly shows the dedication that Prismview and Samsung have to our customers, by not allowing increased costs to impact our product.”

In the short term, production will cost what it did in China — in the long term, Prismview’s clients stand to save much more. SAMEX facilities are Samsung-owned and operated, giving Prismview more control over quality and production schedules. In-house manufacturing streamlines overall production, adding flexibility — and reducing lead-time. And best of all, no part of Prismview’s production process will be impacted by the U.S. Government Section 301 Tariff.

This news comes as many LED companies looked to increase their prices in the face of these tariffs, even going so far as to add the expected increase in fine print, back in September. Prismview didn’t need to follow suit, and will be able to preserve their current prices while still providing their customers with best-in-class products.

In the face of adversity, Prismview had to get creative — and their quick-thinking benefits customers and employees in the long run. “The bottom line is, our prices won’t increase,” says Szczepaniak. “We’re here to deliver the best display boards on the market, at a price that’s fair to our customers.”

Find a digital display that meets your business’s needs and budget.