The Challenge

Having proven the value of the digital design process, the design team at Hyundai America Technical Center, Inc. (HATCI) was looking for a digital display to take their ideating to the next level. The center’s existing screens couldn’t deliver the color definition required of the team’s modern design techniques, and most nascent display technologies lacked the resolution necessary for automotive design. HATCI needed a display that would allow the designers to view their work in true color and high resolution. But more than that, the team needed a screen that could provide a full-size side view of a new vehicle, without taking up valuable floor space in the studio.

The Solution

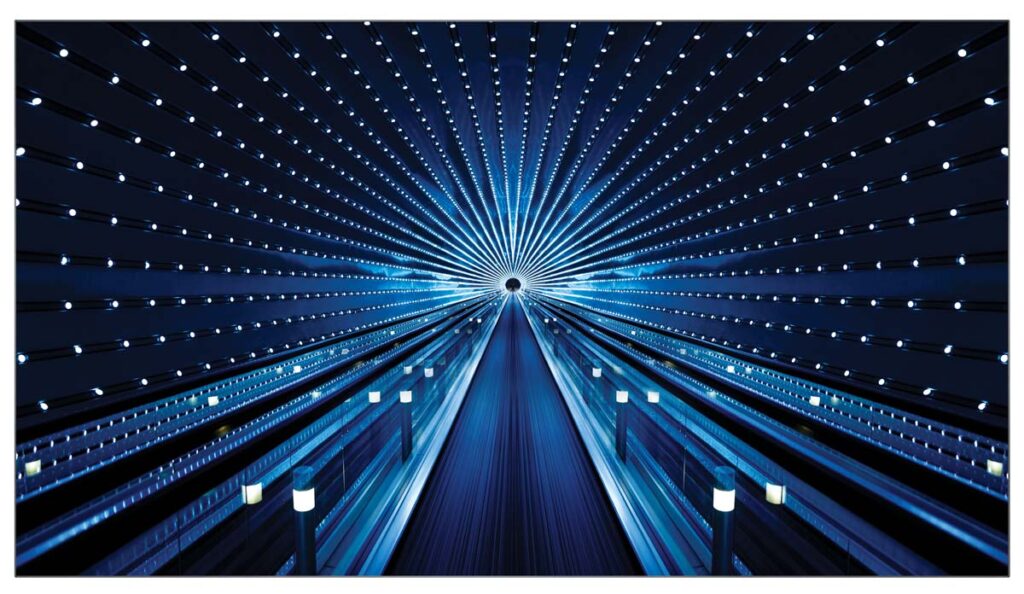

Samsung’s The Wall presented HATCI designers with a perfect solution to their display challenges. Powered by microLED technology, with a pixel pitch of 0.8 millimeters, the display is always sharp and in true color. At the same time, The Wall’s scalable, modular design allows the whole team to view a full-size rendition of their work. The flexible yet compact hardware requires no complex support structure, so the display was able to be installed flush against a wall in HATCI’s design studio.

“The Wall provides by far the best image quality of any LED technology.”

-Paul Helm, IGI Marketing Director

The Results

For the designers at HATCI, seeing their concepts come to life in true color on a high-resolution full-size display removes much of the uncertainty that often accompanies the first look of a physical verification model. The Wall’s visual accuracy, combined with VR imaging software, has given the team the confidence to extend the design freeze much closer to the first verification model. The wall-filling display takes up less studio floor space than previous display solutions, and thanks to its modular construction, can even be repurposed after an end-of-life technology upgrade.

About Hyundai America Technical Center, Inc.

A subsidiary of Korean carmaker Hyundai Motor Company, Hyundai America Technical Center, Inc. (HATCI) is Hyundai’s design, engineering, technology, research and development headquarters for the North American market. HATCI’s activities include automotive design (body, chassis, electronics and trim), evaluation and testing, quality assurance (QA) and drivetrain development. The company also serves the North American market needs of Hyundai affiliate Kia Motors. HATCI has operations in California, Michigan and Alabama.

The Challenge

Bringing full-size automotive design to life

Like other automotive styling studios around the world, HATCI is continually looking for ways to improve their design process. From the first sketch — produced digitally or translated from a hand-drawn sketch — all the way to the design freeze, designers want tools that render lifelike images in high resolution and in a reasonable time frame.

During the design and styling process, HATCI designers require extremely high-quality displays that accurately depict a vehicle’s surfaces and form, including the cabin, through the interaction of color, geometry and light. A high-resolution display allows the design team to thoroughly review the vehicle’s development and accurately assess the impact of subtle changes made over several rounds of revisions.

The team at HATCI had been using a traditional image projector system for years, a three-screen 4K rear projection-based video wall system called the IGI PowerWall. Designers were struggling to achieve accurate styling renditions, particularly in terms of the image quality when viewed in full-size. They searched for a cutting-edge display solution, but there didn’t seem to be many options available that met their needs.

“I kept seeing display technology where the pixels were very obvious, even from a distance,” says David Nikel, manager of design operations for HATCI. “You could just see a lot of noise in the colors.”

HATCI’s new display had to be capable of rendering a full-size side view of a large passenger vehicle in true color and high resolution. Any new display solution would also need to integrate with their existing computer-aided styling (CAS) and computer-aided design (CAD) tools and support future software updates — while taking up minimal physical space in the studio.

Because HATCI is part of a global company with design studios around the world, the team also needed a display that would support real-time remote collaboration with colleagues — on a platform that delivers comparable graphics across all locations and installations.

The Solution

The Wall's microLED technology checks all the boxes

In search of the highest-quality display technology available, HATCI initially switched to LCDs — all the way up to 98-inch screens — before being introduced to Samsung’s microLED technology by Immersion Graphics Inc. (IGI).

An industry-leading provider of large-scale, ultra-high-resolution audiovisual systems for advanced visualization applications, IGI arranged for Nikel to experience The Wall firsthand at the Samsung Executive Briefing Center in Irvine, CA. The microLED display checked all the boxes.

Unlike rear projection, The Wall’s microLEDs produce images that look stunning from any angle, even close up. Millions of bright, micrometer-scale LEDs on a deep black background create unparalleled clarity in true-to-life color — exactly what HATCI’s design team was looking for, says IGI marketing director Paul Helm.

“The Wall provides by far the best image quality of any LED technology,” Helm explains. “This quality is pivotal for HATCI designers to make accurate decisions for future exterior and interior designs.”

To meet HATCI’s objective of displaying a modern passenger car at 1:1 scale, The Wall was installed in the design studio in an 8-by-5 tile configuration, comprising a display 21 feet long and just under 8 feet tall. The team considered installing an even larger display, but settled on these optimized dimensions to deliver the desired image quality within the available space. With the remaining space directly in front of The Wall, HATCI mounted a VR tracking system so designers can examine their designs in 3D.

To harness the full potential of the display’s functionality, HATCI has relied on IGI’s extensive expertise in audiovisual system design, integration and installation. The Wall was up and running in the Irvine design center in less than two weeks, but IGI did significant planning before the physical installation to ensure the display would integrate smoothly with existing CAS/CAD systems, while updating other systems, such as the VR components, where necessary.

The Technology

The Wall

MicroLED technology delivers a bright, colorful viewing experience with Samsung’s The Wall, their most cutting-edge LED display. Black Seal, HDR10+ and Ultra Chroma Technology create pure blacks and true-to-life color and contrast in a seamless design.

The Results

HATCI realizes its digital design dream

As anticipated, Samsung’s superior microLED technology has allowed designers to view and review their designs in true-to-life color at a 1:1 scale. The color vibrancy may even be a catalyst for further system improvements.

“The color is amazing on [The Wall], making me realize we’ve not been understanding color properly,” says Nikel.

To view their designs more accurately across multiple devices, HATCI is considering building an even better color calibration system to render true-to-life colors on all devices, as is the norm in modern film production.

The Wall’s integration with HATCI’s videoconferencing and 3D VR visualization software has also made it easy for the team to collaborate with colleagues around the world, in real time.

“The translation because of software and the reality of the viewing tools we’re using — between VR headsets and screens — allows us to see designs as they ought to be,” explains Nikel. “We’re seeing it in 1:1, the volumes and the form, and the textures of the materials as you expect to see them.”

Before HATCI digitized their design process, it wasn’t uncommon for each studio to be working on up to three full-size clay models simultaneously, which would ideally be brought together in the same studio for a final design workshop. The logistics and material needs made this a difficult and expensive setup. Each studio was typically forced to narrow down their designs to one model early in the process, which ultimately restricted design permutations.

Compared to the traditional design process, HATCI’s digital workflow not only saves time and money but allows the team to move their design freeze very close to the actual fabrication of the first prototype.

“The vibrance of the colors makes it easier to evaluate certain things — and lighting and shading and surfaces. And that’s very special,” says Aytug Yildirim, HTACI’s business operation manager.

Beyond meeting all the display technology requirements, the installation process was equally impressive to Yildirim.

“Another thing that’s amazing about The Wall is that there’s no need to leave any space behind it for projection,” says Yildrim. “That allows it to be installed directly on the wall, meaning that the studio gained 25 feet of real estate over the old projection-based IGI PowerWall system — another reason Hyundai wanted the LED Wall.”

The flexibility of The Wall’s modular design also means that the display can be expanded to accommodate future design work on vehicles that are too large to fit on the current video wall configuration. And when it’s finally time to make another display upgrade, The Wall can be “deconstructed,” allowing the individual panels to be repurposed for other applications, such as conference room displays.

But The Wall has many years left to give.

“I’m pleased with the results, and so are the design managers and chief designer,” Nikel says. “Just about everyone who sees it is pretty much blown away with the system. And we’re just getting started.”