Inventory management is one of the most critical aspects of business operations for any original equipment manufacturer (OEM). Excess inventory on hand ties up cash liquidity in unused raw materials and unsold goods, while shortages can lead to production stoppages, delivery delays and customer dissatisfaction. Inventory management anchors supply chains at OEMs, managing the raw input at one end and the distribution of finished goods to customers at the other.

The traditional linear supply chain is being rebooted in favor of a customer-centric digital supply network (DSN). This evolution is taking form in what’s known as the Fourth Industrial Revolution, or Industry 4.0. More and more enterprises are digitizing their supply chains and implementing DSN principles to achieve efficiency gains, resulting in the creation of smart warehouses and factories. A smart or 4.0 warehouse combines the latest in advanced technology to create a robust system of automation that can completely transform and modernize operational processes for the better.

But what does inventory management look like in lean manufacturing, and how will the adoption of a DSN shape the smart factory of tomorrow?

Improved transparency

Traditionally, OEMs would survey markets and calculate demand, then procure raw materials and plan production runs based on those estimates. Once manufactured, the goods would be distributed to warehouses and hopefully sold rapidly. This isn’t the most efficient method: Market forces are difficult to predict, and a manufacturing pipeline that lacks precise data is not agile.

A lean manufacturing ecosystem, on the other hand, adds data continuously and autocorrects every step of the process, reducing the silo effect between consumer relations management (CRM), enterprise resource planning (ERP), manufacturing execution systems (MES), marketing, production, vendors and suppliers. Thus, each branch of the DSN can see what the other is working with and can work more efficiently.

In the case of inventory management, this means smarter processes for procurement, management of spare parts for assets, warehousing, distribution and order fulfillment.

Smarter procurement

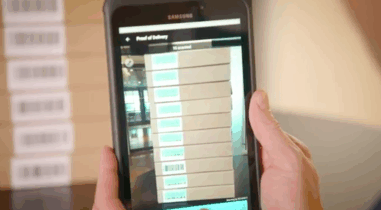

Plant managers in smart factories can access the scheduling of batch production processes and ensure all systems are go for each. In lean manufacturing, the shop floor worker will scan all raw goods used for a process with the help of a barcode scanner attached to a mobile device to automatically pull up the inventory management software.

For example, Samsung’s Galaxy Tab Active3 and Galaxy XCover Pro can be transformed into a mobile barcode scanner with Knox Capture. Knox Capture is powered by Scandit’s award-winning data capture engine and triggers special camera adjustment features within Samsung devices, allowing for quick and easy scanning on the go. This allows workers in smart warehouses and factories to stay productive without having to swap equipment or fiddle with outdated scanner technology.

When a threshold for a product is reached, a trigger programmed by manufacturing personnel can determine when the raw material will be needed again and create a purchase order, which can be routed to the back office and to a plant manager’s mobile device. The manager can then digitally sign the order on their own device and send it to the supplier.

Modernize your factory with mobile

Get your free guide to the mobile technologies that will accelerate your smart factory journey. Download Now

The XCover Pro was designed and built for frontline workers who don’t work at a desk, enabling them to stay active on the move while multitasking. Factory and warehouse workers don’t even need to take off their gloves to sign orders. For those working in highly volatile factory environments, there’s an even more durable model of the XCover Pro: the Ex-Cover Pro D2, developed by Pepperl+Fuchs ecom, the world’s leading manufacturer of mobile devices rated for hazardous areas.

Now, regardless of how harsh the setting, frontline workers can enjoy all the benefits of mobility.

Smarter order fulfillment and warehousing

Scanning barcodes on finished goods as they move from the production line to distribution warehouses relays real-time information about inventory, which can be especially useful during peak demand.

Since inventory management founded on lean manufacturing principles will provide complete transparency across all silos, scheduling can be ramped up or scaled down depending on warehouse stock. Such inventory management also allows OEMs to accept specialty orders for a diverse array of customers, thereby adopting even more of a customer-centric approach.

On a larger level, smart factories can implement effective track-and-trace (T&T) systems, which allow management to precisely pinpoint the location of any raw material or finished product using mobile devices. Warehouses equipped with weather sensors can also alert management about potential hiccups in the quality of stored goods or anticipated deliveries of raw material.

In smart factories and warehouses today, data from a variety of sources is being streamed in real time, sharing information quickly between the ERP software and the MES, and machine learning algorithms are correcting production schedules and moving inventory back and forth intelligently at high speeds.

Mobile devices have played — and continue to play — a critical role in this evolution to the modern smart factory, transforming inventory management all along the supply chain. They can scan barcodes and RFID tags and monitor flow of raw materials and components, work in progress and finished goods, thereby keeping a tight control on inventory. Mobility is key to building a customer-centric DNS and realizing today’s modern smart factory.

Learn more about how Samsung can support your lean manufacturing initiative every step of the way — and download our free guide to accelerating your smart factory journey with rugged mobile devices.