Equipment failures rarely happen according to the manufacturer’s terms, and you can’t always predict where an aircraft will be when a critical part needs replacement. According to the Department of Defense (DoD), more than 610,000 individuals contributed to “DoD maintenance operations” in 2016. Every one of these workers must stay ahead of this material readiness challenge each day as aviators and aircrew step into the cockpit and risk their lives.

From performing inspections to preventive and corrective maintenance tasks, upping mission capable rates requires that technicians have a real-time, holistic view of aircraft performance. Data is key to gaining this understanding and enabling a more proactive approach that can save time and resources. The ability to apply deeper analytics insights is a core tenant of the Condition Based Maintenance Plus (CBM+) approach the DoD is shifting toward, according to the Office of the Assistant Secretary of Defense for Sustainment — and a strategy that mobile solutions like tablets can uniquely support

Deploying Commercial Best Practices in Military Aviation

CBM+, which was designed to put technology and processes in place to achieve greater component availability and reliability, first emerged from the world of commercial airlines. This evidence and need-based approach to maintenance system modernization, acquisition, sustainment and operations goes beyond collecting sensor data and aircraft feeds by layering on additional algorithms and advanced data analytics capabilities — including historical performance. As a result, crews can more accurately anticipate failures and make better decisions around when, where and how to schedule maintenance.

Enhance Aviation Mission Readiness With Mobile Technology

Get your free guide to powering more intelligent aviation missions using TAA-compliant Samsung tablets. Download Now

The DoD has successfully tested the CBM+ approach on C-5M cargo planes, KC-135R tankers and the B-1B bomber, according to Air Force Times. As reported in Defense News, such trials have resulted in operations being able to act more proactively, as opposed to reactively, allowing them to take a more “surgical” approach to maintenance. Seeing such initial success, the U.S. Air Force is now prioritizing a CBM+ strategy. The U.S. Air Force’s 448th Supply Chain Management Wing, for example, is seeing the value of the approach, especially in helping model, predict and mitigate failures, as well as more effectively manage assets to reduce obsolescence in the supply chain, according to Robins Air Force Base.

Mobility Transforms Data Accessibility and Speed-to-Insight

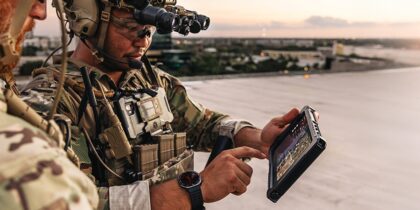

The Air Force has already adopted mobile solutions that enable personnel to work closer to the mission edge on the flight line, and this has laid the groundwork for more high-fidelity data that can be applied to aircraft maintenance. Lightweight, reliable and compliant tablets, in particular, are ideal tools to capture data in unique environments like the flight line and support the shift to a CBM+ approach.

Moreover, security embedded in tablets must be foundational to any “mobile” maintenance solution. Tablets protected by defense-grade mobile security solutions such as Samsung Knox, which is designed to protect from the chip level up, are critical to ensuring data captured and transmitted is always protected. By strictly controlling information access and securing mobile maintenance data, technicians can fulfill their missions with confidence while protecting overall CMB+ system integrity.

Using secure tablets, Air Force maintainers can capture equipment data as they inspect and evaluate part life cycle performance in and around aircraft. This information can then be instantly transmitted and shared to manage diagnostics, make repairs and reduce turnaround time without having to leave the flight line. When CBM+ systems predict issues that require action, technicians can view inventory and schematics and securely access portals, such as the Air Force Enhanced Technical Information Management System (ETIMS), to order replacements right on the spot.

Deploying tablets — such as Samsung’s Galaxy Tab Active2, Galaxy Tab S4, Galaxy Tab S3 and Galaxy Tab A 10.5 — can help aircraft maintenance personnel more quickly and accurately capture data to fuel CBM+ efforts and improve productivity, reduce maintenance man hours and lower operational cost. All of these benefits combined make tablets a powerful addition to an agency’s mobile solution ecosystem to cost-effectively modernize agency flight line operations and enhance mission readiness.

Discover how mobility can transform your tactical operations in this free white paper. Already devised your agency’s mobility plan? Learn how to speedily provision devices as soon as you need them.